Taibo Glass offers empty glass liquor bottles wholesale in different shapes and sizes, we aim to provide clients with a one-stop service. We offer different caps for glass liquor bottles wholesale. Glass bottles are a common storage container for liquor and are widely used in wine bottles on the market. Our empty glass liquor bottles wholesale are suitable for packaging a variety of alcoholic beverages, including whiskey, vodka, sake, liquor, shochu, brandy, limoncello, etc.

-

1000ml Empty Glass Liquor Bottles

Read more -

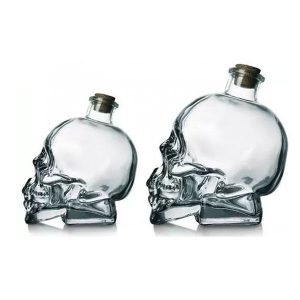

100ml 180ml 400ml 750ml Glass Skull Liquor Bottles

Read more -

100ml 200ml 250ml 350ml 500ml Flat Glass Flask Bottle

Read more -

100ml 250ml 500ml Glass Whiskey Bottle With Cork

Read more -

100ml-750ml Empty Glass Alcohol Bottles

Read more -

150ml Small Glass Liquor Bottles

Read more -

175ml Glass Whiskey Bottle

Read more -

187-500ml Empty Bottles For Liquor

Read more -

1L Glass Brandy Bottle

Read more -

20-50ml Mini Glass Bottles For Liquor

Read more -

250ml Glass Bottle with Stopper

Read more -

300ml 800ml Empty Glass Whiskey Bottle

Read more

Glass has the advantages of high transparency, corrosion resistance, and easy cleaning, so that the appearance and color of the wine can be displayed. Additionally, glass containers are less permeable to oxygen, which helps slow down the rate at which wine oxidizes.

Glass Liquor Bottles Wholesale Advantages

Most glass liquor bottles wholesale are colorless and transparent, and we can clearly observe the internal filling volume, the clarity of the wine, and whether there is precipitation. It is convenient for consumers to choose.

When glass wine bottles are used as packaging containers for alcoholic beverages, because of their chemical stability, there are no leached substances from the container materials. Compared with other containers, it greatly guarantees the safety of food, which is very important for glass bottles to be superior to other containers.

Whether it is beer, liquor or wine, the glass bottle guarantees a complete airtight seal. Unlike most plastic and paper containers, glass containers are not ventilated, which not only prevents the volatilization of the wine in the bottle, but also prevents the influence of the outside air on the wine.

Wholesale glass liquor bottles are cheap and come in various styles. Because the glass wine bottle is formed after melting its raw materials, it can be designed into various shapes according to customer requirements, and its capacity and sealing form can be freely selected.

Custom Glass Whiskey Bottles

In addition to packaging wine, wine bottles also come in more and more shapes, sizes, and colors. We offer various styles of high-end glass whiskey bottles with a transparent and clear appearance and high quality. Our glass spirits bottles include unique designs, such as Boston round, skull shape, flat shape and more.

Noble glass bottles can better highlight the quality and uniqueness of liquor. We also provide OEM and ODM customization services to make glass whiskey bottles more personalized.

We can design 3D drawings of glass liquor bottles and lids according to customers’ ideas, and then design physical samples.

Materials of Glass Liquor Bottles

In the design of liquor glass bottles, the materials can be divided into four types from low to high: blue and white materials (plain white materials), high white materials, crystal white materials, and crystal materials. In addition, there is a relatively low-end glass material: dyeing material.

The higher the material of the glass liquor bottle, the closer the color is to colorless and transparent. Among these materials, high white material and crystal white material are most commonly used. Because of their good whiteness and high transparency, they can better display the color and clarity of liquor.

Customized Colors

We can also provide color coatings. We offer a range of options from clear glass alcohol bottles to amber and other color variants, ensuring we cater to your every need. Glass Bottle color coatings are generally divided into solid colors, transparent colors, and gradient colors, and screen printing is divided into high-temperature screen printing and low-temperature screen printing.

Caps for Glass Alcohol Bottles

In addition to our glass wine bottle products, we also offer compatible caps and closures. Glass alcohol bottles can use various caps to close the product design, such as glass stoppers, T-shaped stoppers, cork stoppers, screw caps, etc. For added style, we can also add customers’ designs and labels to the bottle caps.

T-shaped stopper (Bar-Top Cork) is a cork stopper that combines two materials. A PVC “cap” is installed on the top of the cork, which is shaped like a “T” and can be easily opened without a bottle opener. Its main advantage is that it can be reused and is widely used for storing wine or spirits.

Processing Technology of Glass Alcohol Bottle

Empty Glass Alcohol Bottles as packaging has many advantages such as environmental protection, recyclability, safety, and health. It plays an important role in the field of food packaging. Glass wine bottles that have undergone different processing techniques have a more attractive appearance. Glass packaging is a guide for consumer decision-making, which means that the packaging will effectively promote the brand.

Decal Craftsmanship

The decal process is an important link in the production process of wine bottles. It will directly affect the entire external shape of the wine bottle. The uniformity of the decal will directly reflect the quality of the finished wine bottle.

Baking Process

The manufacturing process of baked glass ripple wine bottle is to stick the plastic decal directly on the blown glass products, send them into the baking kiln by the conveyor belt, and bake them in the heating zone, high-temperature zone, and cooling zone to make glass products with exquisite color patterns. This process is combined with the mold pressing pattern process to obtain glass products with three-dimensional color patterns.

Frosting Technology

On the surface of the glass bottle for vodka, a layer of pattern patterns formed by a flux retardant is silk-screened. After the printed pattern patterns are air-dried, they are frosted. Then after high-temperature baking, the transparent empty pattern appears through the translucent sand surface, forming a special decorative effect.