Xuzhou Taibo Glass is a professional custom glass jar bottles manufacturer, we offer a wide range of glass bottles for food packaging. The main products are glass honey bottles, glass pickle bottles, glass beverage bottles, glass canned bottles, glass wine bottles, glass olive oil bottles, glass candle holders, etc. Glass bottles for food packaging can also be further processed, such as frosting, embossing, spraying, cutting, drilling, etc.

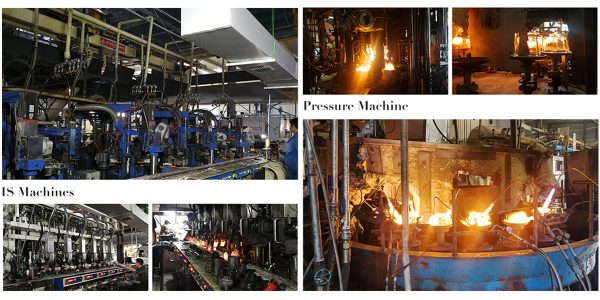

Taibo Glass Factory introduces and learns advanced production equipment and experience, and actively expands production scale and product quantity while continuously improving the quality of glass products.

At present, Taibo glass factory has a complete set of production equipment for welding, sealing, annealing, baking, etc., with a daily output of more than 300,000 pieces, which can guarantee the mass production of customers. The company has more than 200 employees, technicians, professional engineers, and management personnel.

Glass Jar Bottles Manufacturer

Taibo Glass Factory is located in Xuzhou City, Jiangsu Province, specializing in the production of glass wine bottles, custom vodka bottles, red wine bottles, champagne bottles, brandy bottles, tequila bottles, rum bottles, etc.

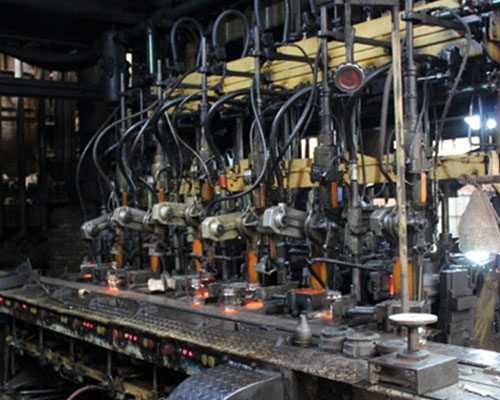

Before the production of glass jars and glass bottles, there are piles of quartz sand, soda ash, limestone, borax and other ores. After the hard work of the workers in the workshop, the chemical reaction of the materials and the high temperature heating, the transparent ones come out. The bottle, after cooling down, is a crystal clear bottle.

Glass Bottle for Food Packaging Production Process

First of all, it is necessary to design and manufacture the mold. The glass raw material uses quartz sand as the main raw material, and other auxiliary materials are melted into a liquid state at high temperature, and then injected into the mold, cooled, cut, and tempered to form a glass bottle.

The molding of glass bottles for food packaging can be divided into three types: manual blowing, mechanical blowing and extrusion molding according to the production method. Glass bottles can be divided into the following categories according to their components: one is sodium glass, the other is lead glass, and the third is borosilicate glass.

One-Stop Service

Taibo Glass Co., Ltd. has implemented a series of scientific and practical management standard systems, and strives to build the company into a one-stop service enterprise for food glass packaging.

Our company’s glass wine bottles and food storage bottles and jars are favored by the market for their high quality, low price, variety, and beautiful appearance. To better meet the needs of customers, we can also customize glass products according to customer requirements. In a short period of time, design new bottle shapes and develop new molds. At the same time, we provide customers with various transportation methods to solve their worries.